Kuchuluka kwa ntchito yamakina owotcherera laserzikuchulukirachulukira, koma zofunikanso zikuchulukirachulukira.Panthawi yowotcherera, mpweya woteteza uyenera kuwomberedwa kuti uwonetsetse kuti kuwotcherera kwa chinthucho ndi kokongola.Ndiye momwe mungagwiritsire ntchito kuwotcherera mpweya moyenera pakuwotcherera zitsulo laser?

Mu kuwotcherera kwa laser, kutchinga mpweya kumakhudza mapangidwe a weld, weld quality, weld malowedwe ndi m'lifupi, etc. Nthawi zambiri, kuwomba mpweya wotetezera kudzakhala ndi phindu pa weld, koma kungakhalenso ndi zotsatira zowononga ngati kugwiritsidwa ntchito molakwika.

Zabwino zoteteza gasimakina owotcherera laser:

1. Kuwomba bwino mpweya wotchinga kumatha kuteteza bwino dziwe la weld kuti muchepetse okosijeni, kapena kupewa kukhala okosijeni.

2. Ikhoza kuchepetsa spotter yomwe imapangidwa mu ndondomeko yowotcherera, ndikugwira ntchito yoteteza galasi loyang'ana kapena galasi loteteza.

3. Ikhoza kulimbikitsa kufalikira kwa yunifolomu kwa dziwe la weld pamene likulimba, kotero kuti weld ndi yunifolomu ndi yokongola.

4. Angathe kuchepetsa weld pores.

Malingana ngati mtundu wa gasi, kuthamanga kwa mpweya ndi njira yowombera zimasankhidwa bwino, zotsatira zabwino zimatha kupezeka.Komabe, kugwiritsa ntchito molakwika gasi wotchinga kumatha kukhala ndi zotsatira zoyipa pakuwotcherera.

Zotsatira zoyipa za kugwiritsa ntchito molakwika gasi wotchinga pa kuwotcherera kwa laser:

1. Kulowetsedwa kosayenera kwa mpweya wotetezera kungayambitse ma welds osauka.

2. Kusankha mtundu wolakwika wa mpweya kungayambitse ming'alu mu weld ndipo kungayambitsenso kuchepa kwa makina a weld.

3. Kusankha mpweya wolakwika womwe ukuwomba kungayambitse kuopsa kwa okosijeni wa weld (kaya kuthamanga kwake kuli kwakukulu kapena kochepa kwambiri), kapena kungayambitsenso zitsulo za weld pool kuti zisokonezedwe kwambiri ndi mphamvu zakunja, kuchititsa weld kugwa kapena kupanga mosagwirizana.

4. Kusankha njira yolakwika yowomba gasi kumapangitsa kuti weld alephere kukwaniritsa kapena kusakhala ndi zoteteza kapena kuwononga mapangidwe ake.

Mtundu wa gasi woteteza:

Ambiri ntchitolaser kuwotchererakutchinga mpweya makamaka N2, Ar, Iye, ndi katundu wawo thupi ndi mankhwala ndi osiyana, kotero zotsatira pa weld ndi osiyana.

Argon

Mphamvu ya ionization ya Ar ndiyotsika kwambiri, ndipo kuchuluka kwa ionization pansi pakuchita kwa laser ndikokwera kwambiri, komwe sikungakhale kothandiza kuwongolera mapangidwe a mitambo ya plasma, ndipo kudzakhala ndi zotsatirapo zina pakugwiritsa ntchito bwino kwa laser.Komabe, ntchito ya Ar ndiyotsika kwambiri, ndipo ndizovuta kuchitapo kanthu ndi zitsulo wamba.zochita, ndipo mtengo wa Ar si wokwera.Kuonjezera apo, kachulukidwe ka Ar ndi waukulu, womwe umapangitsa kuti umire pamwamba pa dziwe la weld, lomwe lingateteze bwino dziwe la weld, kotero lingagwiritsidwe ntchito ngati mpweya wotetezera wamba.

Nayitrogeni N2

Mphamvu ya ionization ya N2 ndi yocheperako, yapamwamba kuposa ya Ar, komanso yotsika kuposa ya Iye.Pansi pa laser, digiri ya ionization ndi pafupifupi, yomwe imatha kuchepetsa mapangidwe amtambo wa plasma, potero kukulitsa kugwiritsa ntchito bwino kwa laser.Nayitrogeni amatha kuchitapo kanthu ndi aluminiyamu aloyi ndi chitsulo cha kaboni pa kutentha kwina kuti apange nitrides, zomwe zidzawonjezera kuphulika kwa weld ndikuchepetsa kulimba, zomwe zitha kuwononga kwambiri zida zamakina a olowa, motero osavomerezeka kugwiritsa ntchito nayitrogeni.Aluminium alloy ndi carbon steel welds amatetezedwa.Nitride yopangidwa ndi zomwe zimachitika pakati pa nayitrogeni ndi zitsulo zosapanga dzimbiri zimatha kulimbitsa mphamvu ya olowa, zomwe zingathandize kukonza zida zamakina a weld, kotero nayitrogeni angagwiritsidwe ntchito ngati mpweya woteteza powotcherera chitsulo chosapanga dzimbiri.

Helium Iye

Ali ndi mphamvu yapamwamba kwambiri ya ionization, ndipo digiri ya ionization ndi yochepa kwambiri pansi pa machitidwe a laser, omwe amatha kulamulira mapangidwe a mtambo wa plasma.Ndi wabwino weld chitetezo mpweya, koma mtengo wa Iye ndi wokwera kwambiri.Nthawi zambiri, mpweyawu sugwiritsidwa ntchito pazinthu zopangidwa mochuluka.Nthawi zambiri amagwiritsidwa ntchito pofufuza zasayansi kapena zinthu zomwe zili ndi mtengo wowonjezera kwambiri.

Pakali pano pali njira ziwiri zowuzira zodziwikiratu zotchinjiriza gasi: kuwomba m'mbali mwa shaft ndi kuwomba kwa coaxial.

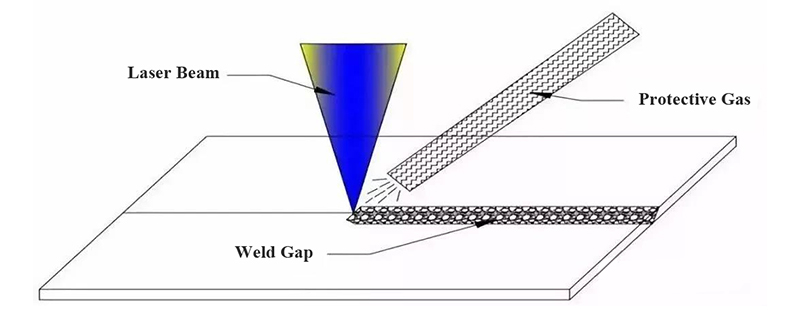

Chithunzi 1: Kuwomba m'mbali mwa shaft

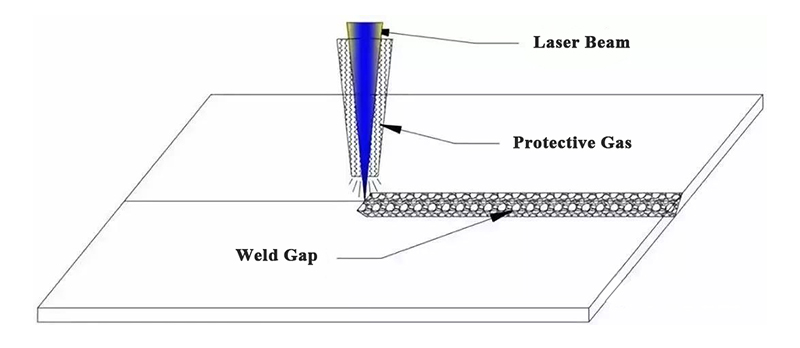

Chithunzi 2: Coaxial Kuwomba

Momwe mungasankhire njira ziwiri zowomba ndikuganizira mozama.Nthawi zambiri, tikulimbikitsidwa kugwiritsa ntchito njira yowomba yoteteza mpweya.

Mfundo yosankhidwa yotetezera njira yowombera mpweya: ndi bwino kugwiritsa ntchito paraxial pamawotchi owongoka, ndi coaxial pazithunzi zotsekedwa ndege.

Choyamba, ziyenera kuonekeratu kuti zomwe zimatchedwa "oxidation" ya weld ndi dzina lodziwika bwino.Mwachidziwitso, zikutanthawuza kuti weld ndi mankhwala anachita ndi zigawo zoipa mu mlengalenga, zomwe zimabweretsa kuwonongeka kwa khalidwe la weld.Ndizofala kuti chitsulo chowotcherera chimakhala pa kutentha kwina.Amachita zinthu ngati mpweya, nayitrojeni, haidrojeni, ndi zina zotero.

Kuletsa weld kukhala "oxidized" ndiko kuchepetsa kapena kuletsa zinthu zovulaza zotere kuti zisakhumane ndi chitsulo chowotcherera pa kutentha kwakukulu, osati chitsulo chosungunula cha dziwe, koma kuyambira pomwe chitsulo chosungunulira chimasungunuka mpaka chitsulo cha dziwe chimalimba. ndipo kutentha kwake kumatsika pansi pa kutentha kwinakwake m’kupita kwanthaŵiyo.

Mwachitsanzo, kuwotcherera kwa titaniyamu kumatha kuyamwa msanga haidrojeni kutentha kukakhala pamwamba pa 300 °C, okosijeni amatha kuyamwa mwachangu kutentha kukakhala pamwamba pa 450 °C, ndipo nayitrogeni imatha kuyamwa mwachangu ikakhala pamwamba pa 600 °C, motero titaniyamu. alloy weld imakhala yolimba ndipo kutentha kumachepetsedwa kufika 300 ° C Magawo otsatirawa ayenera kutetezedwa bwino, apo ayi adzakhala "oxidized".

Sikovuta kumvetsetsa kuchokera kuzomwe tafotokozazi kuti mpweya wotetezera wowombedwa umangofunika kuteteza dziwe la weld panthawi yake, komanso liyenera kuteteza dera lomwe langokhala lolimba lomwe latsekedwa, choncho kawirikawiri mbali ya shaft ya mbali. zomwe zikuwonetsedwa mu Chithunzi 1 zimagwiritsidwa ntchito.Kuwomba mpweya wotchinga, chifukwa chitetezo cha njira iyi ndi chokulirapo kuposa cha njira yotetezera coaxial mu Chithunzi 2, makamaka malo omwe weld wangolimbitsa ali ndi chitetezo chabwino.

Pogwiritsa ntchito uinjiniya, sizinthu zonse zomwe zingagwiritse ntchito mbali ya shaft yotchingira mpweya.Pazinthu zina zapadera, gasi woteteza coaxial okha ndi omwe angagwiritsidwe ntchito, omwe amayenera kuchitidwa kuchokera ku kapangidwe kazinthu ndi mawonekedwe olumikizana.Zosankha zomwe mukufuna.

Kusankha njira zodzitchinjiriza zowuzira gasi:

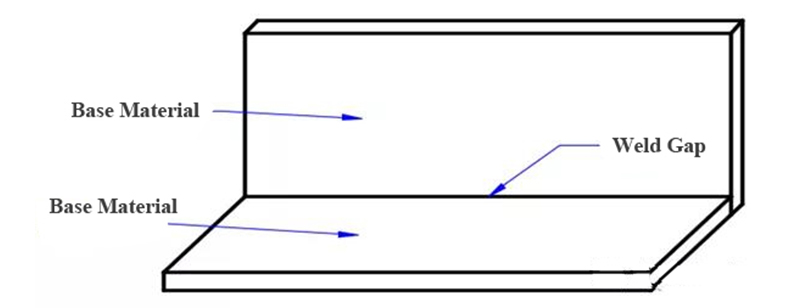

1. Zowotcherera Zowongoka

Monga momwe tawonetsera pa Chithunzi 3, mawonekedwe a msoko wowotcherera wa chinthucho ndi mzere wowongoka, ndipo mawonekedwe olumikizana ndi matako, cholumikizira, cholumikizira chamkati cha ngodya kapena cholumikizira cholumikizira.Ndi bwino kuwomba mpweya woteteza kumbali ya shaft.

Chithunzi 3: Zowotcherera Zowongoka

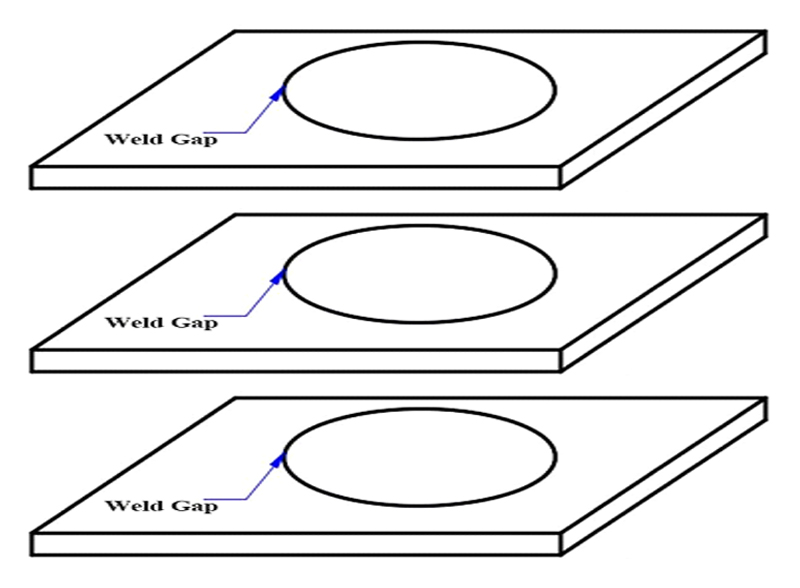

2. Flat chatsekedwa zithunzi welds

Monga momwe tawonetsera pa Chithunzi 4, mawonekedwe a msoko wowotcherera wa mankhwalawa ndi mawonekedwe otsekedwa monga bwalo la ndege, polygon ya ndege, ndi mzere wamagulu ambiri.Ndi bwino kugwiritsa ntchito njira ya mpweya woteteza coaxial yomwe ikuwonetsedwa pa chithunzi 2.

Chithunzi 4: Zojambula Zotsekedwa Zotsekedwa Pathyathyathya

Kusankhidwa kwa mpweya wotetezera kumakhudza mwachindunji ubwino, mphamvu ndi mtengo wa kuwotcherera.Komabe, chifukwa cha kusiyanasiyana kwa zida zowotcherera, kusankha kwa mpweya wowotcherera kumakhalanso kovuta kwambiri pakuwotcherera.Ndikofunikira kuganizira mozama zida zowotcherera, njira zowotcherera, ndi malo owotcherera.Komanso momwe kuwotcherera komwe kumafunikira, kokha kudzera pakuyezetsa kowotcherera komwe kungasankhidwe mpweya wabwino wowotcherera kuti mukwaniritse zotsatira zabwino zowotcherera.

Nthawi yotumiza: May-08-2023