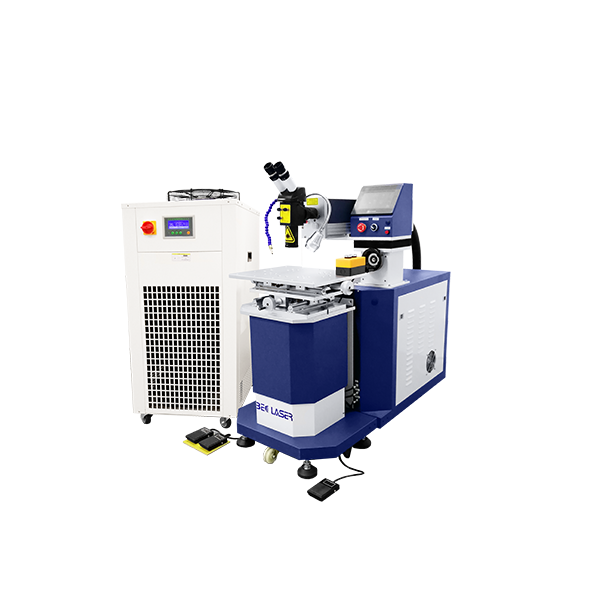

Mold Laser Welding Machine-Manual Type

Chiyambi cha Zamalonda

Masiku ano mashopu owotcherera olondola kwambiri omwe amadziwika ndi nkhungu ya jakisoni wa pulasitiki, kufa ndi kukonza zida ali ndi umisiri watsopano wambiri womwe ukupezeka kuti upititse patsogolo luso lawo lopereka upangiri wapamwamba kwambiri, umisiri, ndi ntchito kwa makasitomala awo.Imodzi mwaukadaulo womwe ukukula mwachangu ndikugwiritsa ntchito makina owotcherera a laser m'malo mwa microscope yachikhalidwe ya GTA.

Chimodzi mwa zinthu zofunika kwambiri popanga kuwotcherera kwa laser kwa Chida ndi Die kapena Mold kupanga ndi kukonza kunali kukulitsa lingaliro la "kusuntha kwaulere".Mwanjira iyi, laser imapanga kugunda kwa kuwala kwa infrared komwe kumalunjika kudzera patsitsi la microscope.Kugunda kwa laser kumatha kuwongoleredwa mu kukula ndi mphamvu.

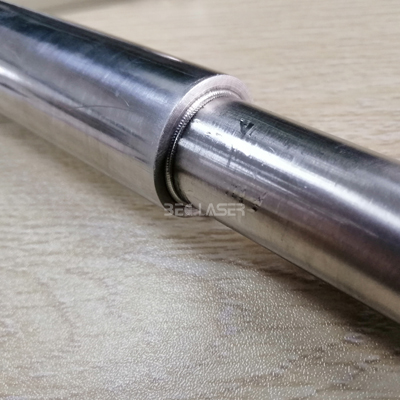

Laser kuwotcherera ndi abwino kwa zosintha ndi kukonza pa nkhungu, zida ndi kufa kaya chifukwa cha kuwonongeka, kuvala ndi kung'ambika, kapena kusintha workpiece kamangidwe.Njirayi ndi yofulumira, yolondola ndipo sichidzawononga malo ozungulira.

Mapangidwe opangidwa ndi anthu molingana ndi ergonomics amapangitsa makinawo kukhala olondola, owoneka bwino, okhazikika, komanso moyo wautali, oyenera kukonza nkhungu mwatsatanetsatane.Ndi ukadaulo wowotcherera womwe uli ndi mphamvu yakutentha kwambiri ya laser, yomwe imayendetsa bwino kuwotcherera ndi kukonza tizigawo tating'ono ta nkhungu, monga: ming'alu, matuza, kupukuta, kung'anima kwa nkhungu, kusindikiza m'mphepete, ndi zina zambiri. nkhungu.Zimapangidwa bwino ndikuyambitsa ukadaulo wapamwamba waku Germany.

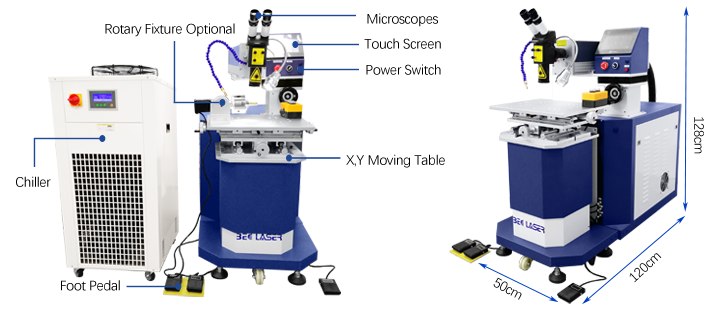

Mawonekedwe

1. Ceramic converging cavity ndi yolimbana ndi dzimbiri komanso kutentha kwambiri, ndipo imakhala ndi moyo wazaka 8-10.Moyo wa nyali ya xenon ndi nthawi zoposa 8 miliyoni.

2. Kugwiritsa ntchito njira zapamwamba kwambiri zotetezera kuwala kuti athetse kupsa mtima kwa maso ndi kuwala panthawi yogwira ntchito.

3. Kukhudza chophimba gulu kusintha magawo, amene ali yosavuta ndi yabwino.

4. Benchi yogwirira ntchito imatha kukwezedwa, ndikusunthira mumiyeso itatu.

5. Kukula kwa malo owala kungasinthidwe.

6. Chipangizo chozungulira chosankha kukonza zinthu za cylindrical annular.

Kugwiritsa ntchito

Ndi oyenera jekeseni mwatsatanetsatane akamaumba, kuponyera, kuwotcherera nkhungu processing ndi mafakitale ena;mitundu yonse ya zitsulo ozizira aloyi, mkulu aloyi zitsulo forging, kuphatikizapo Nickel kuwotcherera chitsulo zitsulo, apamwamba kalasi, kasakaniza wazitsulo zamkuwa, beryllium mkuwa, mkulu-toughness aluminiyamu ndi zinthu zina zitsulo.

Parameters

| Chitsanzo | BEC-MW200 | BEC-MW300 | BEC-MW400 |

| Mphamvu ya Laser | 200W | 300W | 400W |

| Laser Wavelength | 1064 nm | ||

| Max.Single Pulse Energy | 80j | 100j | 120J |

| Mtundu wa Laser | ND: YAG | ||

| Laser Pulse Frequency | 0.1-100Hz | ||

| Pulse Width | 0.1-20ms | ||

| Kuzama kwa Welding | 0.1-1.5 mm | 0.1-2 mm | 0.1-3 mm |

| Benchi yogwirira ntchito | X = 450mm, Y = 350mm (X, Y ikhoza kusinthidwa pamanja, Z-axis ikhoza kukwezedwa) | ||

| Kuwona Systems | Maikulosikopu (chithunzi chowunikira cha CCD kuti chikulitse) | ||

| Control System | Kuwongolera pulogalamu ya Microcomputer | ||

| Kugwiritsa Ntchito Mphamvu | 6kw pa | 10KW | 12KW |

| Kuzizira System | Kuziziritsa madzi | ||

| Mphamvu Yofunika | 220V±10%/380V±10% 50Hz kapena 60Hz | ||

| Kupaka Kukula & Kulemera kwake | Makina: 144 * 66 * 127cm, Madzi ozizira: 87 * 65 * 146cm;Kulemera kwakukulu mozungulira 450KG | ||

Zitsanzo

Kapangidwe

Tsatanetsatane