Cantilever Laser Welding Machine-Wokhala Ndi Mkono Waulesi

Chiyambi cha Zamalonda

The nkhungu laser kuwotcherera makina ndi nthambi ya laser kuwotcherera makina.Mfundo yogwirira ntchito ndikugwiritsa ntchito ma pulses amphamvu kwambiri a laser kuti atenthetse zinthuzo pamalo ang'onoang'ono.Mphamvu ya radiation ya laser imafalikira muzinthuzo kudzera mumayendedwe a kutentha, ndipo zinthuzo zimasungunuka kuti zipange dziwe losungunuka.

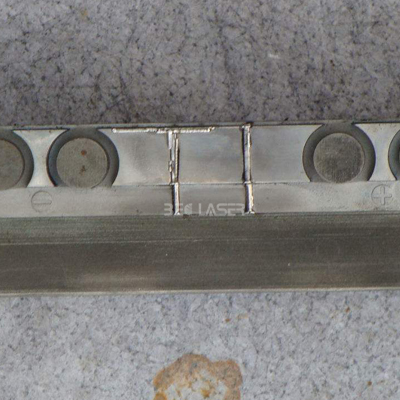

Ndi mtundu watsopano wa njira yowotcherera, makamaka yowotcherera zinthu zoonda zokhala ndi mipanda ndi mbali zolondola.Itha kuzindikira kuwotcherera, kuwotcherera matako, kuwotcherera kwa stitch, kuwotcherera, kusindikiza, ndi zina zambiri, yokhala ndi chiyerekezo chokwera, m'lifupi mwake, ndi madera ochepa omwe akhudzidwa ndi kutentha.Mapindikidwe ang'onoang'ono, kuthamanga kowotcherera mwachangu, kuwotcherera kosalala komanso kokongola, osafunikira kapena kukonza kosavuta pambuyo pakuwotcherera, mawonekedwe owotcherera kwambiri, opanda mabowo a mpweya, kuwongolera kolondola, malo ang'onoang'ono olunjika, kulondola kwamayendedwe apamwamba, komanso zosavuta kuzizindikira.Makina owotcherera amphamvu kwambiri a laser adayambitsidwa, omwe amatha kuzindikira mitundu yosiyanasiyana ya makina owotcherera a laser ndikukonza zida zokulirapo.

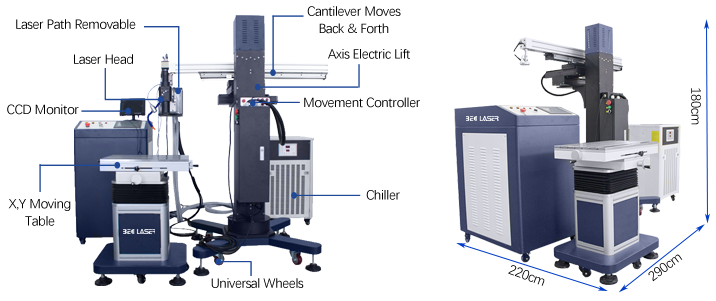

Dzanja la cantilever likhoza kutembenuzidwa mbali zonse ndi ngodya.Ngakhale nkhungu sangathe kusuntha, cantilever mkono akhoza kuyenda momasuka, kwambiri kuthetsa kuwotcherera zovuta, kumapangitsanso ntchito Mwachangu.Makina amatha kuwotcherera malo opapatiza, kuwotcherera kwakuya kukonzanso, sikungapweteke khoma lozungulira.Sichidzasokoneza chinthu cha nkhungu kapena kumira mozungulira dziwe la weld.

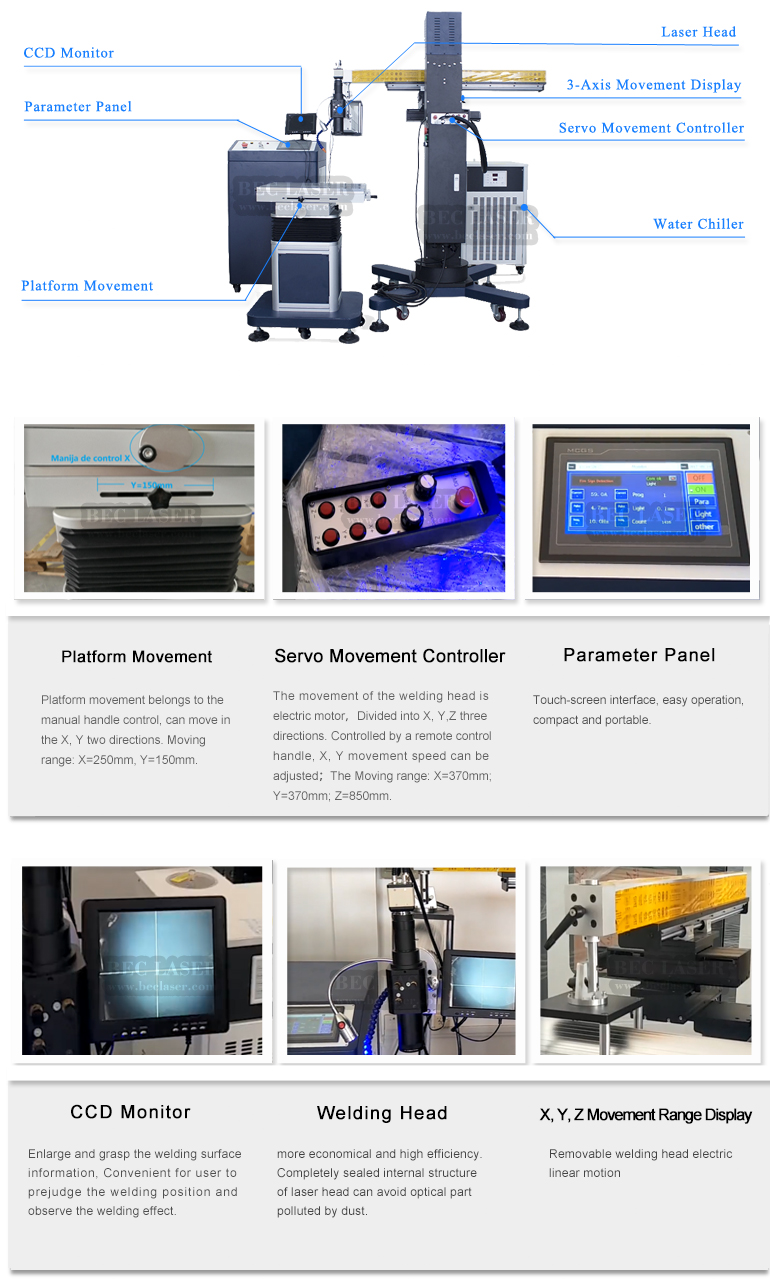

Mawonekedwe

1. Gwero la laser limagwiritsa ntchito ukadaulo wapamwamba waku Germany, wopangidwa ndi gilded.Ili ndi mawonekedwe amphamvu yotulutsa mphamvu, magwiridwe antchito okhazikika komanso kukonza kosavuta.

2. Kukhudza chophimba gulu kusintha magawo, amene ali yosavuta ndi yabwino.

3. Benchi yogwirira ntchito X, Y kusuntha pogwiritsa ntchito wononga mpira wolondola kwambiri komanso kuwala kowongolera njanji yowongoka komanso yosinthika, yokhazikika, yonyamula mpaka 200 kg;

4. Mutu wa laser ukhoza kuyendayenda mmbuyo ndi mtsogolo, kukweza kwamanja, mutu wa laser ukhoza kusinthasintha mosavuta madigiri 180, zosavuta kukonza kuwotcherera mbali iliyonse;

5. Okonzeka ndi ulamuliro wakutali, kusintha kusintha kwa madigiri 360 ngodya malo kuwotcherera.Poona nkhungu yaikulu, safuna workbench, mwachindunji pansi kapena forklift nkhungu kuwotcherera.

Kugwiritsa ntchito

Amagwiritsidwa ntchito pokonza nkhungu zazikulu / kukonzanso.Zida zomwe zimatha kuwotcherera ndi zazikulu: zitsulo zozizira zachitsulo, zitsulo zotentha zachitsulo, chitsulo cha nickel, alloy zitsulo, aloyi ya aluminiyamu yapamwamba, ndi zina. Zitsulo zina monga mkuwa, aluminium-magnesium alloy, titaniyamu ndi platinamu zimagwiranso ntchito.

Parameters

| Chitsanzo | BEC-MW200C | BEC-MW300C | BEC-MW400C | BEC-MW500C |

| Mphamvu ya Laser | 200W | 300W | 400W | 500W |

| Laser Wavelength | 1064 nm | |||

| Max.Single Pulse Energy | 80j | 100j | 120J | 150j |

| Mtundu wa Laser | ND: YAG | |||

| Laser Pulse Frequency | 0.1-100Hz | |||

| Pulse Width | 0.1-20ms | |||

| Benchi yogwirira ntchito | nsanja kusuntha osiyanasiyana: X = 250mm, Y = 150mm, kubala mpaka 200KG | |||

| Cantilever Movement | X=370mm, Y=370mm, Z=850mm | |||

| Kuwona Systems | Microscope kapena CCD monitor mwasankha | |||

| Control System | Kuwongolera pulogalamu ya Microcomputer | |||

| Kugwiritsa Ntchito Mphamvu | 6kw pa | 10KW | 12KW | 16kw pa |

| Kuzizira System | Kuziziritsa madzi | |||

| Mphamvu Yofunika | 220V±10%/380V±10% 50Hz kapena 60Hz | |||

| Kupaka Kukula & Kulemera kwake | Makina: 295x105x195cm, Madzi ozizira: 60x58x108cm;Kulemera kwakukulu mozungulira 510KG | |||

Zitsanzo

Kapangidwe

Tsatanetsatane