3-Axis Laser Welding Machine-Automatic Type

Chiyambi cha Zamalonda

Kuwotcherera kwa laser kumagwiritsa ntchito ma pulses amphamvu kwambiri kuti atenthetse zinthu pamalo ang'onoang'ono.Mphamvu ya radiation ya laser imafalikira muzinthuzo kudzera mumayendedwe a kutentha, ndipo zinthuzo zimasungunuka kupanga dziwe losungunuka.Ndi mtundu watsopano wa njira yowotcherera, makamaka yowotcherera zinthu zoonda zokhala ndi mipanda ndi mbali zolondola.Itha kuzindikira kuwotcherera, kuwotcherera matako, kuwotcherera kwa stitch, kuwotcherera, kusindikiza, ndi zina zambiri, yokhala ndi chiyerekezo chokwera, m'lifupi mwake, ndi madera ochepa omwe akhudzidwa ndi kutentha.Mapindikidwe ang'onoang'ono, kuthamanga kowotcherera mwachangu, kuwotcherera kosalala komanso kokongola, osafunikira kapena kukonza kosavuta pambuyo pakuwotcherera, mawonekedwe owotcherera kwambiri, opanda mabowo a mpweya, kuwongolera kolondola, malo ang'onoang'ono olunjika, kulondola kwamayendedwe apamwamba, komanso zosavuta kuzizindikira.

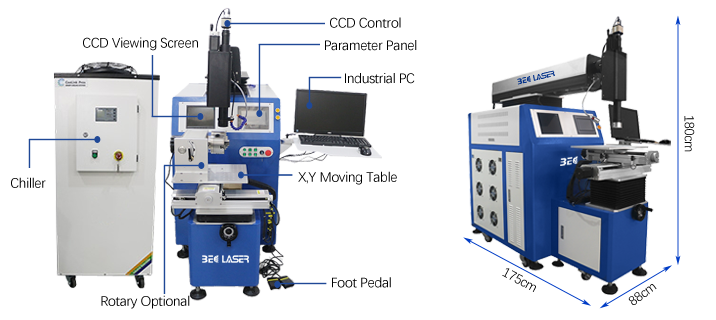

Mapangidwe onse a nkhwangwa zitatu ( nkhwangwa zinayi zilipo), X, Y worktable ikhoza kusinthidwa zokha.Kutalika kwa ntchito benchi ndi laser njira komanso chosinthika.Mapulogalamu kuchita kuwotcherera kufufuza mayendedwe, kuwotcherera malo, mzere wolunjika, bwalo, chowulungika ndi lalikulu etc. aliyense ndege kufufuza ndi losavuta danga geometry kufufuza.Kupatula apo, makinawa angagwiritsidwe ntchito kukonzanso zisankho zazikulu zolemera matani, mothandizidwa ndi trundle-proof trundle ndi kuima kwa phazi lodziyimira pawokha, ndikosavuta kuchotsa kulumikizitsa mankhwalawa.

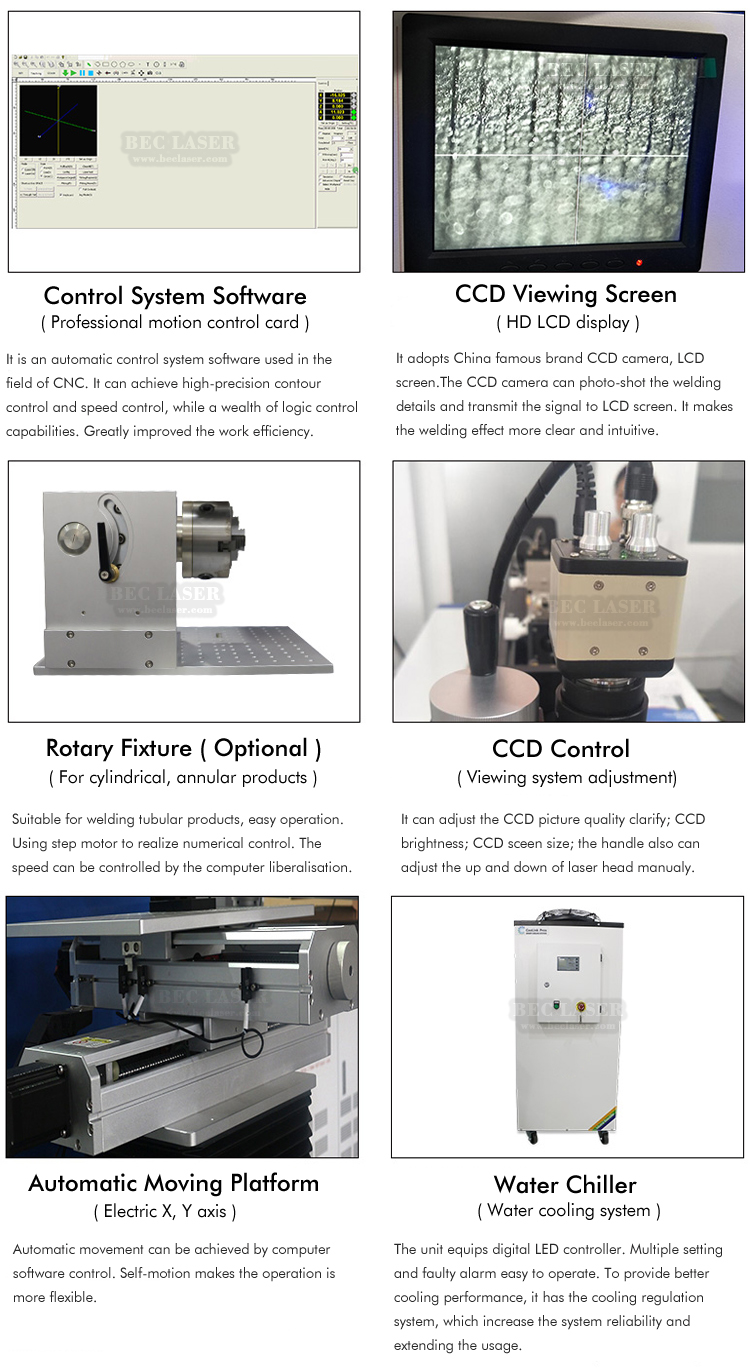

Mawonekedwe

1. Gwero la laser limagwiritsa ntchito ukadaulo wapamwamba waku Germany, wopangidwa ndi gilded.Ili ndi mawonekedwe amphamvu yotulutsa mphamvu, magwiridwe antchito okhazikika komanso kukonza kosavuta.

2. Ili ndi pulogalamu yodziwongolera yokha yomwe imatha kukwaniritsa kuwongolera kolondola kwambiri komanso kuwongolera liwiro, pomwe pali mphamvu zambiri zowongolera malingaliro.Kuchita bwino kwambiri kwantchito.

3. Mphamvu ya laser imalimbikitsidwa ndi di-pulse XE-nyali, yoyendetsedwa ndi pulse nthawi zonse, yokonzedwa ndi pulogalamu yanzeru.

4. Kukhudza chophimba gulu kusintha magawo, amene ali yosavuta ndi yabwino.

5. Benchi yogwirira ntchito imatha kukwezedwa, ndikusunthira mumiyeso itatu yokha.Mutu wa laser ndi benchi yogwirira ntchito imathanso kukwezedwa mmwamba & pansi pamanja.

6. Kuwunika kwa CCD lolani wogwiritsa ntchito kuti awone bwino momwe akugwirira ntchito.

7. Chipangizo chozungulira chosankha kukonza zinthu za cylindrical annular.

Kugwiritsa ntchito

Imagwiritsidwa ntchito pa ma ketulo owotcherera, makapu otsekemera, mbale zachitsulo zosapanga dzimbiri, masensa, tungsten, filaments, ma diode amphamvu kwambiri (ma triodes), ma aluminiyamu aloyi, zotsekera laputopu, mabatire a m'manja, zogwirira zitseko, kufa, zida zamagetsi, zosefera, ma nozzles amafuta. , zinthu zitsulo zosapanga dzimbiri, mitu ya gofu, zinc alloy craftworks, ndi zina zotero.

Parameters

| Chitsanzo | BEC-AW200 | BEC-AW300 | BEC-AW400 | BEC-AW500 |

| Mphamvu ya Laser | 200W | 300W | 400W | 500W |

| Laser Wavelength | 1064 nm | |||

| Max.Single Pulse Energy | 80j | 100j | 120J | 150j |

| Mtundu wa Laser | ND: YAG | |||

| Laser Pulse Frequency | 0.1-100Hz | |||

| Pulse Width | 0.1-20ms | |||

| Benchi yogwirira ntchito | X = 350mm, Y = 200mm, kunyamula mpaka 200KG | |||

| X, Y, Z Movement | X, Y axis zimayenda zokha;osiyanasiyana 300 × 300mm (Mwasankha), Z-olamulira akhoza kukwezedwa. | |||

| Kuwona Systems | Microscope ndi dongosolo lowunikira chithunzi cha CCD kuti chikulitse | |||

| Control System | PLC kapena PC & Microcomputer pulogalamu yowongolera | |||

| Kugwiritsa Ntchito Mphamvu | 6kw pa | 10KW | 12KW | 16kw pa |

| Kuzizira System | Kuziziritsa madzi | |||

| Mphamvu Yofunika | 220V±10%/380V±10% 50Hz kapena 60Hz | |||

| Kupaka Kukula & Kulemera kwake | Makina: 90 * 175 * 182cm, Madzi ozizira: 87 * 80 * 182cm;Kulemera kwakukulu mozungulira 660KG | |||

Zitsanzo

Kapangidwe

Tsatanetsatane